Design and Engineering

Facility Strategies Group provides design and project management services. We have expertise in advanced control systems, central plant, HVAC, and domestic hot water projects, and other building MEP and envelope systems.

Services include:

Project planning, basis of design preparation, life cycle costing, and budgeting

Design drawing and specifications preparation, permitting and plan review, submittal reviews, and progress inspections

Construction administration, including bid document preparation, bid reviews, contractor price analysis, contractor evaluation and selection, change order analysis, and budget tracking and support

Independent construction cost estimating

Mechanical systems assessments, site surveys, preventative maintenance plans, review and prioritization of work order histories

Approach & Methodology

Pre-Design

Once we have a Notice to Proceed, we like to schedule a call or in-person meeting to meet the client team and take a brief look at the buildings, central plant, and mechanical systems to get a sense of the building portfolio, its needs, conditions, and opportunities.

Once we received a task, we arrange for a site visit to visit the building(s), collect some preliminary data, and start to plan what our effort will look like. We also request any drawings, past evaluations, and other supporting information that we can use to understand the owner’s project requirements. We are looking to understand and summarize key objectives, known conditions that the project would seek to resolve, compliance with efficiency and other local or state requirements, and other guiding principles that will inform our plans for site visits and preparation of a Basis of Design document. At this same time, we will provide a project schedule with major milestones for key action steps and deliverables.

Once our task is approved, our site survey visit will walk the project buildings, mechanical spaces, and any systems that abut the scope of work to ensure that once designed, the constructed system will be completed with few issues. We collect details on distances, space conditions, equipment and controls information, determine locations of equipment within rooms and within or outside the buildings, determine vertical shaft locations, possible locations for controls equipment, electrical distribution panel locations and spare capacity, IT network connection / interconnection points, and will verify information included in existing building drawings and survey information. We also determine what Codes come into effect and must be addressed with the scope of work. The site visit will capture conditions in field notes and pictures that will be compiled with our Basis of Design document that accompanies our 50% drawing set.

Design Development

Our Team will develop a design that is responsive to the client’s stated requirements as captured in conversations and formal Owner’s Project Requirements document (or informal OPR that we assemble from notes) and that accurately and completely reflects the work necessary to implement the design and installation of the new system. We have meetings to discuss the basis of design and subsequent drawing packages. These can be had in person or remotely using MS Teams (or equiv), where we can share documents and do page turns on draft drawings. Through meetings we will seek discussion of design options, operations/maintenance considerations, constructability issues, and other appropriate feedback.

Once we are finished digesting collected site information, our team will begin to research communication options for each piece of equipment. We expect mechanical systems are of varying ages, conditions, and status, some recently replaced and others planned for replacement. We will also want to determine whether existing legacy controls can be communicated with, should be replaced or whether existing equipment would be more effectively controlled externally with relays, by replacing aquastats / thermostats with new devices. In some cases, existing equipment will have advanced unit controllers, but these will often use proprietary communications. We’ll evaluate each piece of equipment and prepare a basis of design document including an independent cost estimate for client review with supporting 50% design documents.

One we’ve resolved comments on the basis of design and have a plan to proceed, we will work toward a 75% drawing set (or 90% set as determined by client), start to assemble specifications, and prepare an updated cost estimate. After comments, we’ll prepare a 100% drawing set with final 100% specifications. And again, after resolving comments, we’ll prepare the final set of drawings and specs.

Construction Documents

Next, the final set of drawings and specs will be assembled into a Project Manual / Specification Book. Our Final Cost Estimate will be a detailed line-item estimate to allow preparation of a bid breakdown sheet. Our team does cost estimating on a regular basis for our design and construction-related projects, both for project planning, bid leveling, and for change order evaluations, so we plan to do this work in-house. If the client’s intention is for a “third-party” estimate that is not the design firm, we will plan to outsource the final cost estimate instead, seeking a M/WBE firm where available. The final packages will be reviewed by the client and any changes will be made to the Project Manual, Specification Book, and cost estimates before publishing.

Construction Administration, Commissioning, and Close-Out

Our team will provide support and assistance during the construction bid process, including assistance with the development of the Request For Bids (RFP), responding to pre-bid Requests For Information (RFI), attendance at the Pre-Bid Conference, and prepare bid tabulations. We expect that bidding process will be initiated and managed by client’s procurement and contract staff, but FSG will support as necessary.

We will provide comprehensive construction administration services during the installation of any new equipment, including attendance at weekly project meetings, preparing meeting minutes, written / sketch responses to contractor RFI’s, site visits / inspections as necessary. Site inspections will be initiated to match the work flow expected from the weekly project meetings.

We will also review contractor submittals, shop drawings, and sample graphics (if controls are included) and will review and approve, where warranted, contractor requested change orders, and will review for approval contractor’s pencil and final payment requisitions and will ensure all necessary punch lists and controls integration is completed and will conduct preliminary and final walkthrough and prepare punch-lists. Once the project has been accepted, we will produce as-built drawings and obtain operations and maintenance manuals, all warranties, and administrative credentials into the control system.

For commissioning, FSG prepares all pre-functional and functional test forms, includes a commissioning spec with our bid set, and performs inspections, reviews all submittals and shop drawings, witnesses equipment start-ups, provides TAB reviews, and functionally tests equipment and control systems.

Past & Current Projects

Meltzer Towers Demand Management Pilot

New York City Housing Authority

Glenside Homes Boiler Plant Decentralization Design Engineering

Reading Housing Authority

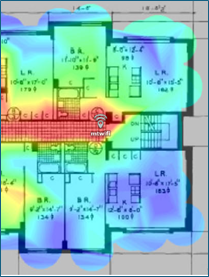

Controls Design for Piloting Wireless Technologies

New York City Housing Authority